Philosophy

(Lab-Crafted) with

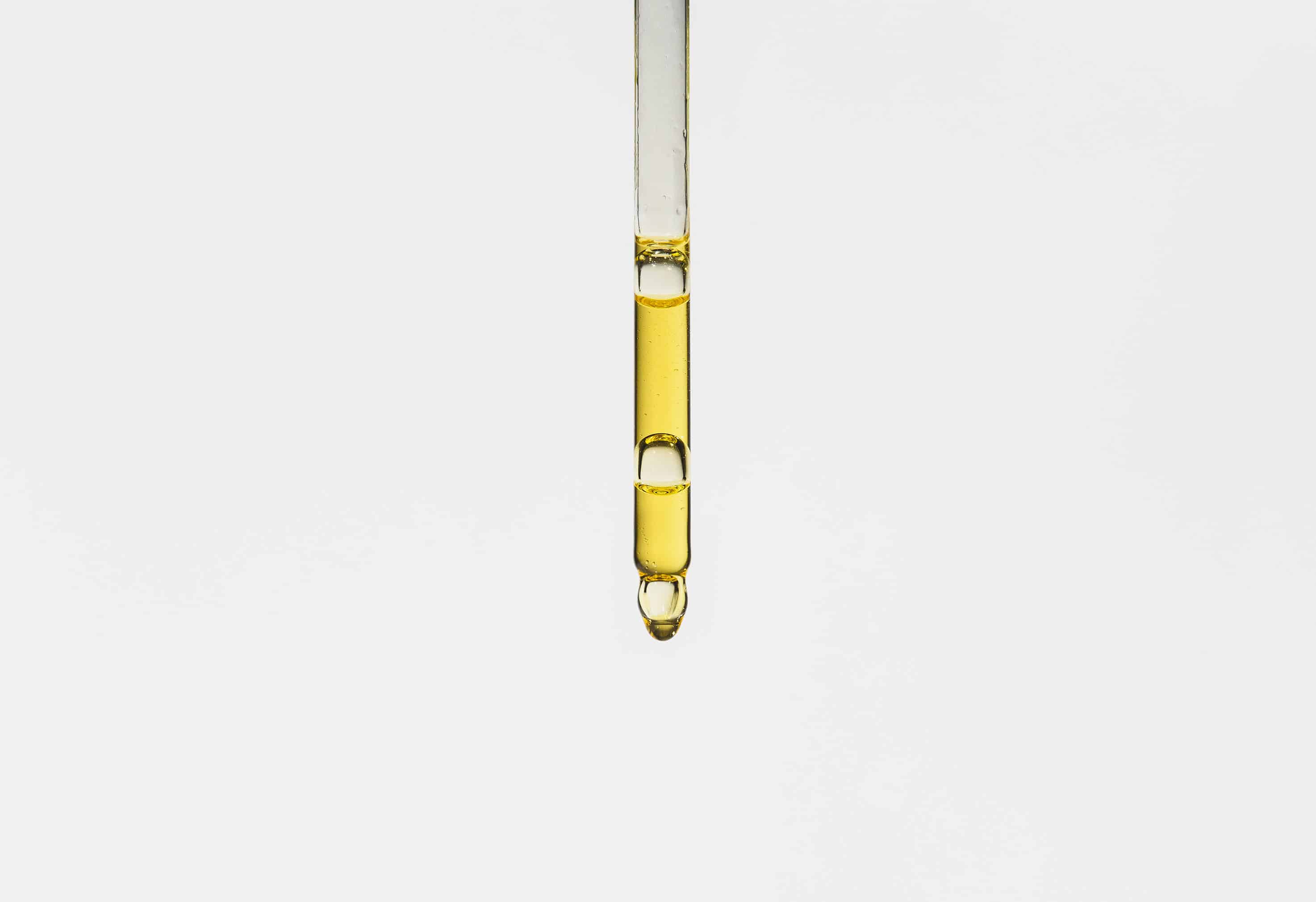

Exceptional Formulas

Manufacturing top quality cosmetics is a scientific process into which many variables enter. Our principles are one of them, but they remain unvarying.

We understand

that the absolute quality is the only formula for success. Trade-offs is for competitors. View more.

We create

cosmetics from state-of-the-art, proprietary ingredients designed by dermatologists and blended by experts.

Meet the Founder MUDr. Alena Pallová.

We help

keep your skin healthy and properly nourished. Beauty and health go hand in hand.

We develop

products for specific uses, selecting active agents accordingly.

We know

how to create effective products with as little environmental footprint as possible.

We never cease

to innovate our manufacturing procedures. We guarantee stable properties of our products with minimum preservatives.

We test

all our products to meet the stringent EU norms and CPNP requirements. We never test on animals.